Electronics may seem like complicated hobby or business to maintain while traveling. Power supplies, multimeters, soldering irons - sure sounds like a lot to carry! And it certainly was, back when you couldn’t fit a full-fledged CPU in a space not much larger than an eye of a needle.

Let me present my traveling electronics (with a dash of drone) workshop which served my needs down to 0402 and 0.5 mm pitch one-sided SMD assembly for close to six months, while fitting into a minor part of a checked in airline bag.

Note: this post contains some product links. They are not sponsored, just added as a matter of completeness.

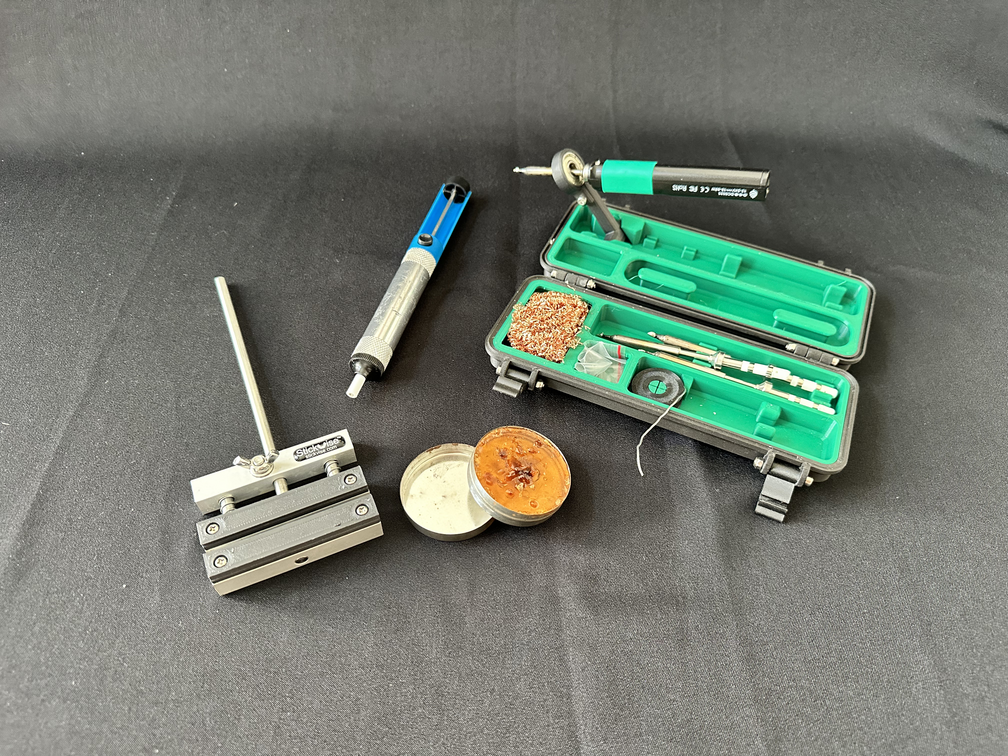

Soldering iron

Pinecil v2 has served my needs well, both during travel and while at home.

I carry the standard tip, as well as 3 additional ones:

- fine chisel tip (TS-BC2) - for connectors and certain SMD packages

- fine sharp tip (TS-ILS) - for precision, low clearance soldering

- knife tip (TS-KU) - perfect for desoldering and soldering large items

It travelled in a rugged case containing all the necessary accessories, including a reel of solder, stand and a brass brush.

A vise is a necessity, and a Stickvise was my choice. Carry printed/bought vise jaws for replacement if you’re going for long!

Reflow hot plate

Another activity not commonly associated with having a small desk footprint is reflow soldering - a process where solder paste is applied to a printed circuit board through a stencil, components are placed, and the entire assembly is heated up in order to transform the paste into solder.

That’s actually valid for the most part - there are major disadvantages to using a hot plate for reflow, the main one being lack of ability to do double-sided assembly using a single tool.

This has not turned out to be an issue for me, however, as I’d assembled mostly prototyping boards, and didn’t mind the occasional hand soldering session.

I used a Miniware MHP30, offering a 30 x 30 mm working field. The small size worked out for me, as I was working on drone components, which conserve space out of necessity.

In its natural environment:

I also printed out these Stickvise jaws for MHP-30.

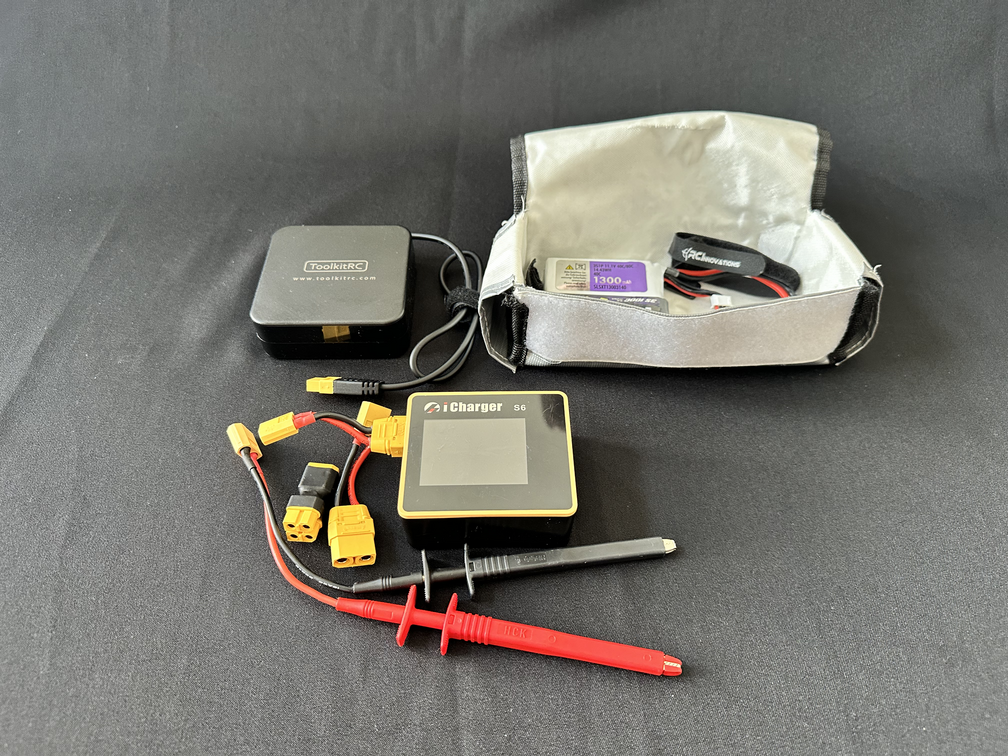

Power supply

When diving into the world of drones, I was pleasantly surprised to learn that almost every battery charger comes with a variable voltage power supply with current limitation features, and high current supply abilities to boot.

I picked iCharger S6 for this purpose. I don’t regret that choice, but today I would go out of my way to make or buy something USB C-powered, such as ARK Electronics’ LiPow.

Supplying power to the charger proved to be a problem - it accepts DC input voltage of 9 - 32 V, so a USB C decoy cable providing XT60 output at 20 V - a ToolkitRC SC100 - seemed like a logical pick. That was, sadly, a mistake on my part. While I’m sure the IC that’s embedded in the cable can provide the advertised 5 A of output current, my unit managed to burn out quarter way through the trip, never having lived up to half of its current potential. The cable kept getting hot enough to never leave unattended. Sometimes you just cannot cheat thermal characteristics.

Oddly enough, I wound up coming back with a power supply made by the same manufacturer - the Toolkit RC ADP100, which hasn’t given me the slightest problem ever since.

Test instruments

While I don’t think the Owon HDS200 series of hand-held oscilloscopes has a place on a bench next to Rigol or Tektronix devices, it definitely did well for me in terms of functionality per cubic unit of luggage space. Featuring a multimeter and a waveform generator, it genuinely left nothing to be desired for my basic use-cases.

On the other hand, here’s my nomination for an unlikely candidate for every embedded engineer’s workbench: the Flipper Zero. The built-in converters replaced a bunch of discrete devices I would have to haul around. Thanks to its programmability, it can also act as a screen to any project with a decently capable microcontroller.

Hand tools

Of course, I couldn’t leave my trusty pliers behind. Grabbed some of their friends, too, so they wouldn’t be lonely.

- Pliers

- Wire stripper

- Engineer PAD-11 crimpers (my main use-case was crimping JST-GH, commonly used in drones)

- Allen keys

- Precision tweezers

- Side cutters

Consumables

Cables, connectors I frequently use, and crimps. Add in some Kapton tape, heatshrink and zip-ties and you’ve got yourself a modern-day MacGyver load-out.

I also brought a bag full of bags full of spare just-in-case SMD components, picked from the most used ones in my library. Electronics already seems like a pretty wasteful business with all the shipping and plastic involved, so I’d decided to pack what I needed in terms of components and work within these confines. These actually proved very useful, both for repair and original work.

Drone stuff

Just the drone, some spare standoffs, bolts and propellers, as well as a Steam Deck working double duty as a remote controller and entertainment.

General remarks

As you will notice, USB C was the name of the game for powering many of these devices. The USB PD standard has been a true lifesaver for integrating common power delivery protocol into an effective footprint of a USB C connector (FUSB302, my beloved). There is no excuse not to use it to power your projects, even as a hobbyist.

While I’m sure my bag looked suspicious on the luggage scanners, a fair part of its weight being electronics and related chemicals, to my knowledge it never got opened and made it through multiple airports in Europe and Asia unharmed.

If you’re concerned about humidity wrecking havoc on these delicate devices, don’t be. My laptop came back with more visible wear on it than any of these did.

Throughout my trip, I was able to move two projects from their inception, past the prototype stage. If you’re interested in what I’ve been working on, check out my drone electronics company, Spacedock.io.